Theme: From your imagination to a 3D model

3D PRINTING 2020

“International Conference on 3D Printing and Additive Manufacturing” will be held in Dubai during November 23-24, 2020. Major attractions of this event would revolve around keynote presentations, oral presentations and poster presentations. This year we are focusing on the theme “From Your Imagination to a 3D Model". The term "3D printing" is progressively utilized as an equivalent word for Additive Manufacturing. It transforms digital 3D models into strong solid by structure them up in layers. The innovation was first invented during the 1980s, and since that time has been utilized for rapid prototyping (RP). 3D Printing has been applied in engineering and healthcare since the beginning of 20th century. For the manufacturing of custom prosthetics and dental inserts, it was first utilized and after that on wards the medicinal applications for 3D printing has advanced essentially. 3D printing is the path towards making cell structures in a limited space using 3D printing innovation, where cell limit and suitability are spared inside the printed construct. 3D printing adds to huge advances in the medical field of tissue engineering by allowing for research to be done on innovative materials called biomaterials. 3D bio printers are streamlined to have the capacity to print skin tissue, heart tissue, and veins among other essential tissues that could be appropriate for surgical treatment and transplantation. This innovation is utilized in the fields of adornments, footwear, mechanical structure, design, engineering and construction (AEC), automotive, aviation, dental and medical industries, education, geographic data frameworks, structural building, and numerous others.

Session-1: Digital Light Processing (DLP) 3D Printing

DLP (Digital Light Processing) is a similar process to stereolithography in that it is a 3D printing process that works with photopolymers. The major difference is the light source. DLP uses a more conventional light source, such as an arc lamp with a liquid crystal display panel, which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SL. Also like SL, DLP produces highly accurate parts with excellent resolution, but its similarities also include the same requirements for support structures and post-curing. However, one advantage of DLP over SL is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-2: Impact of 3D Printing on Manufacturing Industry

The world has seen many intriguing manufacturing technologies so far, however 3D printing has truly grabbed everybody's eye in the course of recent years. Not only does it have the potential to create something through an entirely unique process, but it also has the capability to render some production lines useless. If consumers are able to 3D print their favourite everyday consumer goods using a 3D printer at home, the manufacturing industries will face a serious drawback. On a different note, 3D printing has opened up new opportunities for production, factory maintenance, and R&D, since acquiring spares for a machine has never been easier. 3D printing is an innovation with a blended impression, however a great many people are seeing that the process will exceed the cons.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-3: Advances in 3D Printing & Additive Manufacturing

Advanced technologies for 3D printing and additive manufacturing and how these technologies have changed the face of direct, digital technologies for rapid production of models, prototypes and patterns. Because of its wide applications, 3D printing and additive manufacturing technology has become a powerful new industrial revolution in the field of manufacturing. The evolution of 3D printing and additive manufacturing technologies has changed design, engineering and manufacturing processes across industries such as consumer products, aerospace, medical devices and automotive. The objective of this book is to help designers, R&D personnel, and practicing engineers understand the state-of-the-art developments in the field of 3D Printing and Additive Manufacturing.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-4: 3D Printing Materials

After over a year of research, countless filament spools, and hundreds of hours of printing, our team is proud to present the Ultimate 3D Printing Materials Guide. Covering over a dozen of the most popular materials in use today, this guide will help you select the best material for your next project or improve the quality of your prints with tips from our experts. Use the tags below to quickly sort the materials based on their characteristics, or view our extensive Filament Properties Table for a detailed side-by-side comparison. Once you have selected a material, view a detailed article with pros and cons, hardware requirements, best practices, pro-tips, example projects and more! Whether you’re new to 3D printing or an advanced user looking to experiment with a new material, this guide has everything you need to make the most of your next project.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-5: Innovations in 3D Printing

The world of 3D printing has the possibility of creating a newer, better future. From increasing the effectiveness of foreign aid to creating a more sustainable future. The possibilities presented to us by 3D printers have allowed us to imagine a better future. Unfortunately, the majority of objects that can be created are subject to the size of each respective 3D printer. Therefore, we can only print to a minimal extent. Alternatively, 2016 has seen an incredible advancement in the 3D printing sector. Below, we have curated a list of six innovations that will change the future of business and production.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-6: 3D Printing in Space and Aerospace

The airplane business incorporates a scope of business, modern and military applications, and is included divisions that plan, make, work and keep up the air ship or shuttle. Among the principal promoters of 3D printing, the airline industry is a driving force in the evolution of this technology for both manufacturing end-use parts and prototyping. Airlines depend on 3D printing to alleviate supply chain constraints, limit warehouse space and reduce wasted materials from traditional manufacturing processes. Rapidly producing aircraft parts on demand saves enormous amounts of space, time and money.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-7: Applications in Health Care & Medicine

The method has been applied to (and used by) a wide range of industries, including medical technology. Frequently therapeutic imaging procedures, for example, X-rays, computed tomography (CT) scans, magnetic resonance imaging (MRI) scans and ultrasounds are utilized to deliver the first computerized model, which is in this manner sustained into the 3D printer. It has been forecast that 3D printing in the medical field will be worth $3.5bn by 2025, compared to $713.3m in 2016. The industry’s compound annual growth rate is supposed to reach 17.7% between 2017 and 2025. There are four core uses of 3D printing in the medical field that are associated with recent innovations: creating tissues and organics, surgical tools, patient-specific surgical models and custom-made prosthetics.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences |

Session-8: 3D Printing in Automotive Industry

Since the early days, 3D printing in automotive manufacturing has witnessed unprecedented industry adoption. With the emerging economical and environmental concerns, there is a pressing need to rethink the way automobiles are designed and manufactured. The automotive industry ought to adapt to this shift in paradigm quickly. This is where 3D printing in automotive design swiftly steps up. 3D printers not only help the aesthetic design of vehicles but it also has the prowess to deliver working prototype in record turnaround time. 3D printing in automotive design fosters innovation, creativity and limitless possibilities; empowering tomorrow’s transportation landscape.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences

Session-9: 3D Printing in Biomaterials

3D Printing promises to create complex biomedical gadgets as per PC configuration utilizing patient-specific anatomical data. Since its underlying use as pre-careful representation models and tooling moulds, 3D Printing has gradually developed to make exceptional gadgets, implants, scaffolds for tissue engineering, diagnostic platforms, and drug delivery systems. In this audit, the significant materials and innovation propels inside the most recent five years for every one of the regular 3D Printing technologies (Three Dimensional Printing, Fused Deposition Modeling, Selective Laser Sintering, Stereolithography, and 3D Plotting/Direct-Write/Bioprinting) are described. Examples are highlighted to illustrate progress of each technology in tissue engineering, and key confinements are recognized to motivate future research and advance this fascinating field of advanced manufacturing.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences

Session-10: Layered Manufacturing and Additive Fabrication

Additive fabrication refers to a class of manufacturing processes, in which a part is built by adding layers of material upon one another. These processes are inherently different from subtractive processes or consolidation processes. Subtractive processes, such as milling, turning, or drilling, use carefully planned tool movements to cut away material from a workpiece to form the desired part. Consolidation processes, such as casting or molding, use custom designed tooling to solidify material into the desired shape. Additive processes, on the other hand, do not require custom tooling or planned tool movements. Instead, the part is constructed directly from a digital 3-D model created through Computer Aided Design (CAD) software. The 3-D CAD model is converted into many thin layers and the manufacturing equipment uses this geometric data to build each layer sequentially until the part is completed.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences

Session-11: Polymers in 3D Printing

Polymers are macromolecules made of many rehashing subunits called monomers. These monomers are coordinated by covalent bonds where atoms share electrons being a strong union. The procedure to deliver a polymer is known as polymerization reaction. Thermoplastic polymers are really important in Additive Manufacturing. Thermoplastics are polymers which relax when they are warmed and harden as they cool. These polymers are utilized for plastic 3D prints, prominently Selective Laser Sintering (SLS). There are a few prominent thermoplastics that can be utilized with this procedure, delivering a variety of results depending on their base properties.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences

Session-12: Additive Manufacturing and 3D Robotics

Additive manufacturing and robotics. One technology relies on steady, repetitive motion to build each infinitesimal layer, over and over again. The other technology is renowned for its repeatability and control. It's as if they were made for each other. It's a match made in disruptive technology, in the future of manufacturing. Robots are not only enabling additive manufacturing, they're tending 3D printing machines (which are also robotic), automating AM post-processing, and allowing architects to envision new, flexible ways to build the world around us. Expanding our possibilities. These technologies are used to develop machines that can substitute for humans and replicate human actions.

3D Printing Summit 2020 | 3D Printing & Additive Manufacturing Conferences | 3D Bio printing Conferences | 3D Printing Conferences | 3D Printing Innovations | 3D Printing Design & Engineering Conferences | 3D Printing 2020 | 3D Printing in Aerospace Conferences | 3D Printing in Robotics Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing in Medical Conferences | 3D Manufacturing Conferences

Scope and Importance:

The 3D printing market was esteemed at USD 10.58 billion out of 2018, and is relied upon to arrive at an estimation of USD 49.01 billion by 2024, at a CAGR of 29.48% over the forecast period 2019-2024. Toward the finish of 2018, America Makes declared it was granting USD 1.6 million to a joint undertaking between Arizona State University and the ASTM International Additive Manufacturing Center of Excellence. In the prior months of 2019, the project aims to advance post-processing methods for SLM parts.

With technological advancements and product innovations, use of 3D printing technology has found various application in a wide variety of areas, such as jet engines, advanced prosthetics, and even living tissue (with a potential to disrupt the entire manufacturing industry).

- The industry is being constantly driven by technological developments, which guarantee higher adaptability and empower faster design. Further, manufacturers have realized the advantages that 3D printing offers, such as optimizing material, labor, and transportation costs. Manufacturing units have had the option to eliminate material wastage using 3D printing.

- Governments over the world have just begun putting resources into R&D on 3D printing, which has positively affected on technology propagation and adoption. For example, the Dutch government put an extra USD 150 million in 3D printing-related research and development.

- However, the market remains constrained by high costs of equipment needed to deploy 3D printing on an industrial scale. The absence of a worldwide principles body directing producers likewise confines the market development.

Source of revenue and analysis of the 3D bio printing market:

Bio printing materials

3D bio printers

Services and ancillary equipment

With the classification into metals, polymers, ceramic, and bio-ink, the bio printing materials segment accounted for the major shares of the 3D bio printing market. The polymers are broadly utilized in bio printing material that involves both common and synthetic materials. Owing to the favourability of the natural polymers, they are preferred for engineering tissues and organs. Regular polymers involve collagen, chitin, chitosan, hyaluronic corrosive, and chondroitin sulfate. The broad utilization of polymers in bio printing materials will add to the development of the market throughout the following four years.

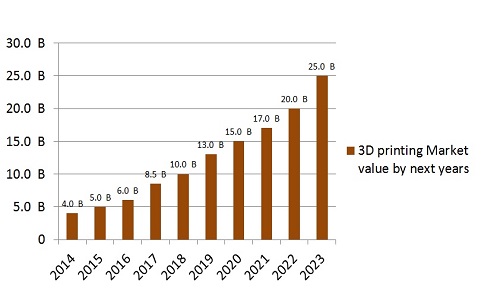

Market Growth of 3D Printing in the last and upcoming ten years:

3D printing materials have noteworthy development in Middle East locales. Different 3D printing assembling organizations have seen setting-up in the Middle East locales during the most recent couple of years. It's demonstrating that the pattern is probably going to proceed throughout the following 10 years with the accessibility of minimal effort crude materials alongside expanding assembling yield in these areas.

Middle East 3D Printing Materials market value is anticipated to expand at a CAGR of 16.7% during the forecast period and along with that the Middle East 3D printing materials market volume is expected to register a CAGR of 11.2% during the forecast period.

3D Printing Market Value by next 10 years:

Industries Associated with 3D Printing

USA

Stratasys – Minneapolis, Minnesota, USA

Autodesk – San Rafael, California, USA

Hyrel 3D – Norcross, Georgia, USA

M3D – Fulton, Maryland, USA

Europe

3D Filaprint, UK

3D Gbire, UK

Addition Design, UK

Am 3D, UK

SLM Solutions, Germany

3D Hubs, Germany

EOS e-Manufacturing, Germany

Leap Frog 3D Printers, Netherlands

3D Print Pulse, Netherlands

Middle East

Advanced Manufacturing Services, Australia

3D Systems, Australia

IRIS 3D Solutions, Dubai

The 3D Shape, Dubai

3D PrintDXB, Dubai

3D Printing Industry, India

3D Print.com, India

Manufacture 3D, India

Global universities:

Harvard’s School of Engineering and Applied Sciences, USA

Princeton University, USA

Cornell University, USA

University of Tornoto, Canada

University of Lethbridge, Canada

University of Sheffield, UK

University of Nottingham, UK

University of Exeter, UK

University of Melbourne, Australia

University of Sydney, Australia

University of Auckland, New Zealand

University of Victoria, New Zealand

Federal University of Santa Catarina, Brazil

University of Nicosia, Germany

Nanyang Technological University, Singapore

National University, Singapore

University of BITS Pilani, Dubai

University of Indian Institute of Technology, India

Conference Highlights

- Digital Light Processing (DLP) 3d printing

- Impact of 3D printing on manufacturing industry

- Advances in 3D printing & additive manufacturing

- 3D printing materials

- Innovations in 3D printing

- 3D printing in space and aerospace

- Applications in health care & medicine

- 3D printing in automotive industry

- 3D printing in biomaterials

- Layered manufacturing and additive fabrication

- Polymers in 3d printing

- Additive manufacturing and 3d robotics

To share your views and research, please click here to register for the Conference.

To Collaborate Scientific Professionals around the World

| Conference Date | November 23-24, 2020 | ||

| Sponsors & Exhibitors |

|

||

| Speaker Opportunity Closed | Day 1 | Day 2 | |

| Poster Opportunity Closed | Click Here to View | ||

Useful Links

Special Issues

All accepted abstracts will be published in respective Our International Journals.

- Journal of Bioengineering & Biomedical Science

- International Journal of Advance Innovations, Thoughts and Ideas

Abstracts will be provided with Digital Object Identifier by